- All shop categories

- New products

- Frames

- Maintenance

- Tools

- Resources

Tools

3D PuffPro® - TOOL for 3D / Puffy Embroidery

Product number: 571322

Product number 2: Z-009-3988

Product number 2: Z-009-3988

Professional Tool for 3D Embroidery Foam Clean-Up

Achieve a flawless finish on your puff embroidery – with the 3D PuffPro®!

The 3D PuffPro® is designed for the safe and effective removal of excess 3D puffy foam from embroidery designs. With two versatile ends, it offers full control over your clean-up process – without risking fabric or thread damage.

Two specialized ends for various cleaning tasks

Protects garments from damage caused by sharp tools

Ensures clean, professional 3D embroidery results

Durable stainless steel construction

Made in the USA – Patent pending

Used with the appropriate heat application, the 3D PuffPro® helps you create high-quality, professional embroidery finishes – ideal for commercial and creative embroidery applications.

Adjusting Device Needle Height

Product number: 601003206

Product number 2: Z-003-0710

Product number 2: Z-003-0710

ADJUSTING TOOL FOR F-HEAD

Product number: 601005952

Product number 2: Z-003-0716

Product number 2: Z-003-0716

Bag with ZSK Logo

Product number: 668009

Product number 2: Z-009-5243

Product number 2: Z-009-5243

The Bag is a practical storage solution for the tools used by operators and service technicians of ZSK embroidery machines. It provides ample space for frequently used tools and accessories, helping to keep everything easily accessible during daily operation.

The bag is made from durable nylon and is securely closed with a zip. The tool bag features the ZSK logo with the “Made in Germany” addition printed on it.

Features

Material: robust, easy-care nylon fabric

Colour: black with ZSK logo and “Made in Germany” print

Closure: zip across the full bag width

Ideal for storing tools and accessories for ZSK embroidery machines

Lightweight, compact and durable

Whether in the workshop, at the customer’s site or on the go, this bag keeps your tools safe, organised and always within reach.

Note: The bag is supplied without contents.

BELT TENSION GAUGE

Product number: 656291

Product number 2: Z-004-2243

Product number 2: Z-004-2243

IGAT TECO-PRO Belt Tension Measuring Device: Precision for Your ZSK Embroidery Machine.

Precise belt tension is one of the **foundations for flawless embroidery** and the longevity of your ZSK embroidery machine. Whether V-belts, timing belts, or flat belts: an exact tension is crucial to prevent **thread breaks, skipped stitches, and premature wear**. The IGAT TECO-PRO measuring device is your indispensable partner to secure the performance of your valuable machine in the long term.

Why the TECO-PRO is indispensable for your ZSK Embroidery:

Ensures Your Stitch Quality: Precisely tensioned belts guarantee the exact synchronisation of all moving parts. The result: Fewer thread breaks, no skipped stitches, and consistently **high stitch quality** that delights your customers.

For Consistent Results Across Multiple Machines: Uniform belt tension on several machines ensures that you always achieve **identical, reproducible results** for the same jobs – crucial for quality and efficiency in series production.

Maximises Machine Lifespan: Protect your investment! Correctly adjusted belts reduce wear on bearings, motors, and the belts themselves. This means **less downtime** and a significantly longer service life for your ZSK machine.

Accurate Measurement, Always Reliable: Equipped with state-of-the-art microprocessor technology, the TECO-PRO measures pre-tension between 10 and 600 Hz. Its acoustic measuring principle makes it **independent of belt material, colour, or light influences** – for consistently precise and reproducible results.

Effortless Handling, Even in Tight Spaces: The ergonomic design of the device allows for comfortable one-hand operation. Thanks to the small measuring head and flexible gooseneck, you can easily reach **hard-to-access belts** in your ZSK embroidery machine.

Ready for Immediate Use: The IGAT TECO-PRO is supplied as a complete set, including a USB charging cable, Euro plug, and a stable transport hard case – perfect for professional use.

Invest in the precision and longevity of your ZSK embroidery machines. With the IGAT TECO-PRO, you secure the top quality of your embroidery and the efficiency of your production.

DEVICE FOR NEEDLE LEVEL

Product number: 601001844

Product number 2: Z-003-0708

Product number 2: Z-003-0708

Grease Brush

Product number: 706032

Product number 2: Z-000-0684

Product number 2: Z-000-0684

Precision Grease Brush – Your Aid for Perfect Machine Care

Regular and precise lubrication is essential for the longevity and smooth operation of your valuable sewing and embroidery machine. Our specially developed Precision Grease Brush is the ideal tool for applying grease exactly where it's needed – even to the smallest and most hard-to-reach mechanical components.

Unlike conventional brushes, this grease brush features exceptionally fine and dimensionally stable synthetic bristles. These allow for controlled and economical dosing of the grease, without leaving lint or residue. The bristles are also resistant to oils and greases and are easy to clean, ensuring hygienic and efficient application with every maintenance session.

The ergonomically shaped handle fits comfortably in your hand, allowing for secure guidance and maximum precision. Whether it's gears, guides, or other heavily stressed moving parts – with this grease brush, you'll ensure optimal reduction of friction and wear, prevent costly repairs, and maintain your machine's performance in the long term.

Your Advantages at a Glance:

Precise Grease Distribution: Ideal for fine mechanics and hard-to-reach areas.

High-Quality Synthetic Bristles: Dimensionally stable, lint-free, and resistant to lubricants.

Extends Lifespan: Protects mechanical parts from wear and corrosion.

Ergonomic Design: For comfortable and precise application.

Easy Cleaning: Reusable for sustainable machine care.

Invest in the care of your embroidery machine – with our Precision Grease Brush, you're choosing professional maintenance for lasting precision and enjoyment from your embroidery.

Locking Pin 136° (128°)

Product number: 601005914

Product number 2: Z-004-2258

Product number 2: Z-004-2258

Drive Shaft Locking Pin for Precise Fixation.

During maintenance and adjustment work on your embroidery machine, it's often crucial to secure the drive shaft in an exact position. Our locking pin has been specially developed for this task, offering you the highest precision and security.

The pin is simply inserted into the designated opening of the drive shaft and locks securely into place. This reliably holds the shaft in the **precise position of, for example, 136° or 128°** (depending on the setting marked on your machine), enabling you to carry out error-free work on critical components.

NEEDLE EASE TOOL

Product number: 570933

Product number 2: Z-008-8720

Product number 2: Z-008-8720

Needle Ease – The Hassle Free Way to Change Embroidery Needles

Changing embroidery needles can be tricky and time-consuming – but with Needle Ease, the process becomes much easier and more precise. This patented tool ensures that every needle is perfectly aligned before installation. Thanks to a built-in click mechanism, you’ll know instantly when the needle is in the correct position—eliminating guesswork and frustration.

Regular needle changes are essential for smooth embroidery and uninterrupted workflow. Needles should be replaced frequently, especially when using specialty threads or after extended use. Since an embroidery needle has an average lifespan of just 8 hours, using Needle Ease helps prevent thread breaks and machine downtime.

Crafted from brushed stainless steel, this durable tool is designed for round shank industrial needles and is a must-have for any embroidery workshop.

Make needle changes effortless – with Needle Ease!

How to Use Needle Ease:

Hold Needle Ease with the "NEEDLEEASE.COM" logo and the black set screw facing up. With one hand, pull back the coloured collar. Using your other hand, insert the new needle into the slot at the tip of the tool.

Slowly release the collar and gently rotate the needle until you hear or feel a distinct "click". This confirms that the needle is correctly positioned and ready for installation. You can now insert the needle into your embroidery machine with confidence.

To remove Needle Ease, simply pull back the collar again and slide the tool off the needle.

📌 Please note: The pull-back collar may come in different colours.

💡 Pro tip for easy handling:Apply slight pressure with your thumb on the needle shank while rotating it—this helps it lock into place smoothly.

Needle Orientation Magnet

Product number: 571207

Product number 2: Z-009-3181

Product number 2: Z-009-3181

Needle Alignment Magnet – for accurate needle positioning

A correctly aligned needle is essential for clean embroidery and smooth machine performance.

Even a slight twist of the needle can cause uneven stitching or thread breakage.

The Needle Orientation Magnet allows you to check and adjust the position of the needle eye within seconds. For best results, the needle eye should sit slightly to the right of the centre – never to the left.

The magnet helps you align the needle precisely and insert it securely into the machine.

This compact tool ensures consistent machine operation and perfect embroidery quality on every design.

Push type gun

Product number: 667035

Product number 2: Z-001-0115

Product number 2: Z-001-0115

High Pressure Push Type Gun – Precision Hand Pump for Oils & Lubricants

This special-purpose plunger gun is designed for the pinpoint application of oil, petroleum, aerosols and additive-enhanced lubricants. Its black powder-coated finish, rigid delivery tube and follower piston ensure reliable performance even in demanding workshop environments.

Key Features:

Pressure rating up to 150 bar – ideal for accurate high-pressure lubrication

Output of 0.5 cm³ per stroke for precise dosing

Reservoir capacity 150 cm³ – plenty for routine servicing

Supplied with flat & pointed nozzles plus yellow protective cap

Corrosion-resistant black powder-coated body

Typical Applications:

Recommended for maintenance on ZSK embroidery machines and any precision equipment where targeted high-pressure lubrication is required.

How to Use:

Fill the reservoir, position the nozzle and squeeze the handle. Each stroke delivers exactly 0.5 cm³ of lubricant. Fit the yellow cap after use for clean storage.

Safety Adjustment Pin

Product number: 601001614

Product number 2: Z-004-0370

Product number 2: Z-004-0370

Safety Adjustment Pin for Precise Adjustment Work on the Embroidery Head

Adjustments to the embroidery head demand the utmost precision. However, using a sharp and fragile needle for such fine-tuning carries risks: it can easily break and even lead to injuries.

Our **Safety Adjustment Pin** has been specifically designed as a safe and robust alternative. Made from the same material as a high-quality embroidery needle, it perfectly simulates its properties without the associated dangers.

This allows you to make **safe and precise** adjustments to the embroidery head without fear of needle breakage or injury. It protects not only you, but also your embroidery machine and your material.

Application

You need the Safety Adjustment Pin for tasks such as adjusting the needle height after replacing the needle bar. Together with the Needle Height Adjustment Body the correct needle height can then be set.

Schmidt MST 2000 Yarn Tension Meter

Product number: 656282

Product number 2: Z-009-0046

Product number 2: Z-009-0046

MST 2000 – Electronic Thread Tension Measuring Device

The MST 2000 is a high-precision electronic measuring device for determining and adjusting thread tension on embroidery and sewing machines. Thanks to its motor-driven pull-off mechanism, it ensures constant withdrawal speeds and guarantees reliable measurement results. The precise adjustment of thread brakes under consistent conditions enables optimal stitch quality.

Technical Data & Features

Measuring Range: 1 to 2000 cN

Measurement Accuracy: ±1 % Full Scale ±1 Digit (typically ±0.5 % Full Scale)

Motor-Driven Pull-Off Mechanism: Constant 9 m/min for consistent measuring conditions

Three Display Options:

Numeric

Numeric with bar graph (trend display)

Numeric with graphic (time-tension diagram)

Flexible Display: Rotatable in 90° steps for optimal readability

Data Recording via USB Interface: Storage capacity for up to 60,000 measurements

Five Storage Programmes: Organised and structured measurement management

Limit Value Setting: Adjustable MIN and MAX values with display warning when exceeded

Switchable Force Units: cN, g, N, or lb

Zero Setting: Automatic zero-point calibration regardless of measurement position

Fast Data Acquisition: Internal processing at 1 kHz

Statistical Values: Storage of MIN, MAX, last measurement, average, and standard deviation

Fine Adjustment: Adaptation of stored calibration curves when measurement material differs from calibration material

Scope of Delivery

MST 2000 thread tension measuring device in case

Vacuum base for stable positioning

Li-Ion battery for mobile use

USB power adapter with four country adapters (EU/USA/UK/AUS-NZL)

User manual (German or English, please specify when ordering)

Precision by Hans Schmidt & Co GmbH

The renowned manufacturer Hans Schmidt & Co GmbH is known for tested and high-quality control instruments in the textile industry. With the MST 2000, you receive a premium device for thread tension measurement that combines maximum accuracy and user-friendliness.

Order now and ensure precise thread tension!

Screwdriver for stitch plate inserts

Product number: 601005943

Product number 2: Z-000-1025

Product number 2: Z-000-1025

Easy changing of stitch plate inserts - with the ZSK screwdriver for stitch plate insertsScrewdriver specially developed for use on ZSK embroidery machines for changing stitch plate inserts on ZSK embroidery machines.The low height of the special screwdriver makes it easy to reach the stitch plate insert under the needles.

Special screwdriver with interchangeable bits

Product number: 601003955

Product number 2: Z-003-2043

Product number 2: Z-003-2043

Special Screwdriver for Work on ZSK Embroidery Machines

This tool stands out due to its **low profile**. It allows you to reach screws even in **tight and hard-to-access places**, such as for loosening the screws of the needle plates directly behind the needles on the embroidery head.

The screwdriver is supplied with two common bits:

a Phillips-head bit and

a flat-head bit.

The screwdriver bits can be quickly and easily exchanged by loosening the side grub screw, offering you flexible application possibilities for maintenance and adjustment tasks.

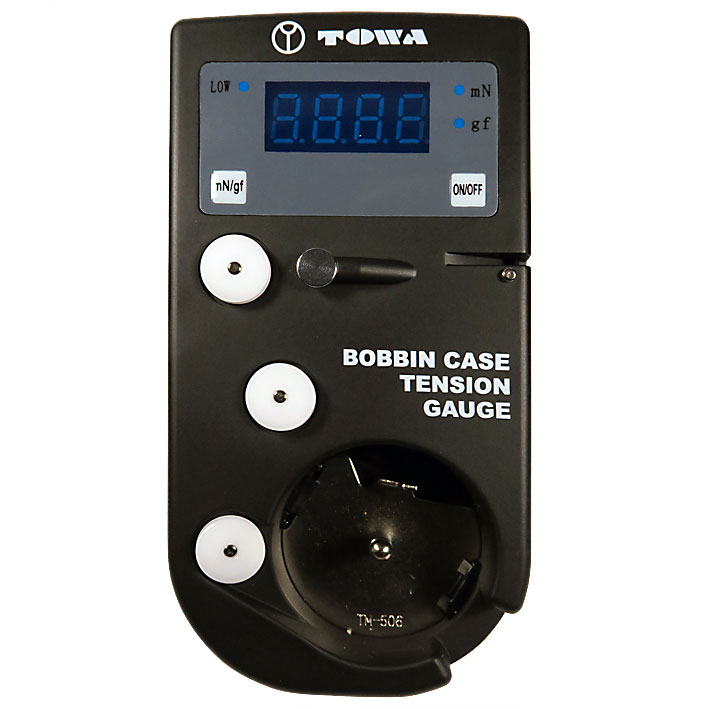

TOWA THREAD TENSION GAUGE DIGITAL

Product number: 570800

Product number 2: Z-008-2182

Product number 2: Z-008-2182

TOWA Digital Thread Tension Gauge

Digital measuring device for measuring the upper and lower thread tension on embroidery machines.

The correct thread tensions of the upper and lower thread are important settings to achieve a perfectly harmonious embroidery pattern.

Features and advantages of the TOWA thread tension meter

A device to measure and adjust the upper thread tension and lower thread tension

Easy to read large digital display

Two different measuring units:mN (milli Newton) - scale from 0 to 4500 | gF (gram force) - scale 0 to 600

Energy saving functionsAutomatic energy saving function: If the device is not in use, it switches to energy saving mode after 50 seconds to save energy.Automatic switch-off function: The device switches itself off after 5 minutes of non-use.

Built-in thread cutter

Why is it important to adjust the thread tension correctly?

The correct thread tensions of the upper and lower threads are important parameters to achieve a perfect and harmonious embroidery pattern.

Signs that the upper thread tension is not correct:

Thread loops form on the surface

Visibility of the upper thread on the back of the design

Thread breakage

The embroidery is distorted

Signs that the bobbin thread tension is not correct:

Visibly loose bobbin thread on the underside of the embroidery

The bobbin thread is pulled upwards and is visible in the design

Poor embroidery quality

TOWA TM-1 THREAD TENSION GAUGE

Product number: 570632

Product number 2: Z-000-8675

Product number 2: Z-000-8675

TOWA TM-1 Thread Tension Gauge

Digital measuring device for measuring the lower thread tension on embroidery machines.

The correct thread tensions of the lower thread is an important setting to achieve a harmonious embroidery pattern.

Features and advantages of the TOWA TM-1 thread tension meter

A device to measure and adjust the lower thread tension

Easy to read analog display

One measuring unit: mN (milli Newton) - scale from 10mN to 400mN

Built-in thread cutter

Ready for immediate use: no batteries or special settings are required.

Why is it important to adjust the thread tension correctly?

The correct thread tensions of the lower threads is an important parameter to achieve a perfect embroidery pattern.

Signs that the lower or bobbin thread tension is not correct:

Visibly loose bobbin thread on the underside of the embroidery

The bobbin thread is pulled upwards and is visible in the design

Poor embroidery quality

Wire for Cleaning K-Head

Product number: 680183

Product number 2: Z-001-0130

Product number 2: Z-001-0130

ZSK Tool Bag – Basic Set

Product number: 270015903

Product number 2: Z-000-0755

Product number 2: Z-000-0755

The ZSK Tool Bag – Basic Set includes a carefully selected range of tools and materials for maintenance and service work on ZSK embroidery machines. All tools are neatly organised in a durable nylon bag with ZSK logo and always ready for use – ideal for technicians and operators in daily operation.

Each component is perfectly matched to the requirements of ZSK embroidery machines.

Contents

1 × Phillips screwdriver PH2, blade length 100 mm

1 × Hex screwdriver, size 2, straight

1 × Slotted screwdriver 0.5 × 3.0 × 75 mm

1 × Slotted screwdriver 0.4 × 2.5 × 75 mm

1 × Slotted screwdriver 0.5 × 3.0 × 80 mm

1 × VM needle plate

1 × Set of hex keys (5 sizes)

1 × Atlantic machine oil, resin- and acid-free, 100 ml

15 × Grub screws, internal hex 2 mm

1 × Scissors, Nippes Solingen

1 × Brush for greasing

1 × Plastic tweezers

Features

Durable black nylon bag with ZSK logo

High-quality, long-lasting tools for maintenance and service

Optimally assembled for ZSK embroidery machines

Compact, well organised and ready for use

Note: The bag is also available without contents – ideal for storing your existing tools. Bag with ZSK Logo (Item No.: 668009)